Modern manufacturing is defined by precision, speed, and the ability to adapt to increasingly complex product designs. As industries push for lighter, stronger, and more intricate components, traditional machining methods are no longer sufficient on their own. CNC machining, supported by advanced manufacturing services, has become the backbone of high-performance production across global industries. Within this space, companies such as JTR Machine contribute significantly by combining technical expertise with reliable manufacturing solutions.

The Evolution of CNC Machining in Industrial Production

CNC machining has progressed far beyond basic cutting and drilling operations. Early CNC systems were primarily used for straightforward parts, but today’s machines are capable of producing highly complex components with exceptional accuracy. This evolution has been driven by advancements in software, tooling, and machine design.

As product designs become more detailed and tolerances tighter, manufacturers must rely on sophisticated machining processes to meet expectations. CNC machining enables consistent quality across batches, reduces manual intervention, and ensures repeatability, which is essential for industries where precision directly impacts performance and safety.

Understanding Multi-Axis Machining Capabilities

One of the most important advancements in CNC technology is multi axis cnc machining. Unlike traditional three-axis machines, multi-axis systems can move tools and workpieces simultaneously along additional axes. This capability allows manufacturers to machine complex geometries in a single setup.

By reducing the need for multiple repositioning steps, multi-axis machining improves accuracy and minimizes production time. It also enables the creation of intricate features such as undercuts, curved surfaces, and angled holes that would otherwise require secondary operations.

Why Complex Designs Demand Advanced Machining

Industries such as aerospace, medical devices, and high-end industrial equipment increasingly rely on complex designs to improve performance and efficiency. These designs often involve organic shapes, tight internal features, and high-precision surfaces.

Multi-axis CNC machining supports these requirements by allowing tools to approach the workpiece from optimal angles. This results in better surface finishes, tighter tolerances, and fewer errors. For manufacturers, this means the ability to take on challenging projects that demand both creativity and technical precision.

Integrated Manufacturing Services as a Strategic Advantage

CNC machining is most effective when supported by integrated manufacturing services. Leading manufacturers now offer end-to-end solutions that include design support, prototyping, machining, finishing, and inspection.

This integrated approach streamlines production and reduces the risk of miscommunication between different stages. Clients multi axis cnc machining benefit from faster lead times, improved consistency, and a single point of accountability. For manufacturers like JTR Machine, integration allows better process control and the ability to deliver complete solutions rather than isolated services.

Industry Applications and Practical Examples

Multi-axis CNC machining is widely used across industries where precision and complexity are critical. In aerospace manufacturing, it enables the production of lightweight structural components with complex contours that reduce weight without sacrificing strength.

In the medical sector, precision-machined parts such as surgical instruments and device housings require smooth finishes and exact dimensions. Multi-axis machining ensures these components meet strict regulatory and functional requirements.

Industrial automation and robotics also rely heavily on complex machined components. Accurate alignment and consistent performance are essential, and advanced CNC processes help achieve these goals reliably.

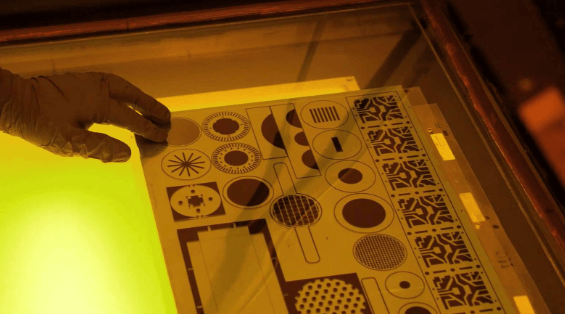

Quality Control in High-Precision Manufacturing

Quality assurance is central to CNC and manufacturing services. When producing complex components, even minor deviations can lead to functional failures or costly rework.

Manufacturers implement rigorous inspection processes throughout production. From material verification to in-process checks and final inspection, quality control ensures that every component meets design specifications. Advanced measurement equipment and experienced quality engineers play a key role in maintaining consistent standards.

A strong quality culture not only ensures compliance but also builds long-term trust with clients.

The Role of Skilled Professionals

Despite the high level of automation in CNC machining, skilled professionals remain essential. Programmers, machinists, and engineers are responsible for optimizing tool paths, selecting appropriate cutting strategies, and resolving production challenges.

Multi-axis machining, in particular, requires advanced programming knowledge and practical experience. Skilled operators understand how to balance speed, accuracy, and tool life while maintaining surface quality.

Continuous training and workforce development are therefore critical investments for any serious manufacturing operation.

Supporting Innovation Through Prototyping

Innovation often begins with rapid prototyping. CNC machining allows manufacturers to produce functional prototypes that closely resemble final products. This enables engineers to test designs, identify potential issues, and make improvements before full-scale production.

Multi-axis machining enhances prototyping capabilities by accommodating complex designs without extensive retooling. This flexibility is especially valuable for research and development teams working under tight timelines.

By supporting rapid prototyping, CNC manufacturers help clients accelerate innovation and reduce development risks.

See also: Series Kleiner Perkinsann Azevedotechcrunch

Sustainability and Efficiency in CNC Operations

Sustainability has become an important consideration in modern manufacturing. Efficient CNC machining processes can reduce material waste, energy consumption, and overall environmental impact.

Multi-axis machining contributes to sustainability by minimizing setups and reducing scrap caused by repositioning errors. Optimized tool paths and efficient machine utilization further improve resource efficiency.

Manufacturers that prioritize sustainable practices not only support environmental goals but also improve cost efficiency and operational performance.

Building Long-Term Manufacturing Partnerships

In the CNC and manufacturing services industry, long-term success depends on reliability and collaboration. Clients value partners who understand their technical requirements, communicate transparently, and deliver consistent results.

Manufacturers that focus on partnership rather than transactions provide added value through design feedback, process optimization, and flexible production support. This collaborative approach strengthens relationships and supports mutual growth.

The Future of Advanced CNC Manufacturing

The future of CNC machining will continue to be shaped by automation, digital integration, and data-driven decision-making. Smart factories, real-time monitoring, and predictive maintenance are already transforming production environments.

As product designs grow more complex, demand for multi-axis machining and integrated manufacturing services will increase. Manufacturers that invest in technology, skilled personnel, and quality systems will be well positioned to lead the next phase of industrial production.

In this rapidly evolving landscape, CNC and manufacturing service providers remain essential drivers of precision, innovation, and global manufacturing excellence.