Would you like to harness laser technology to cut materials precisely? Laser cutting machines have become an innovative and superfast solution for many craftsmen. When you need to shape wood panels or create intricate metal designs, these machines are a good choice. Thus, they are a resource in your workshop to increase your productivity and creativity. But, which laser cutter will help you meet your project needs? You have to check the features and performance standards before investing in the laser cutter.

Understand Types of Laser Cutters

CO2 Laser Cutting Device

CO2 laser cutters use CO2 gas and other gases charged by electric discharge. The average wavelength of these machines is 10.6mm. You can use CO2 laser cutters to cut:

- Glass

- Wood

- Acrylic

- Plastic

Crystal Laser Cutters

These machines produce beams with smaller wavelengths and are best for cutting thicker materials. A smaller wavelength also means higher intensity and better focus. Use the laser cutter to cut materials like:

- Ceramics

- Metals

- Plastics

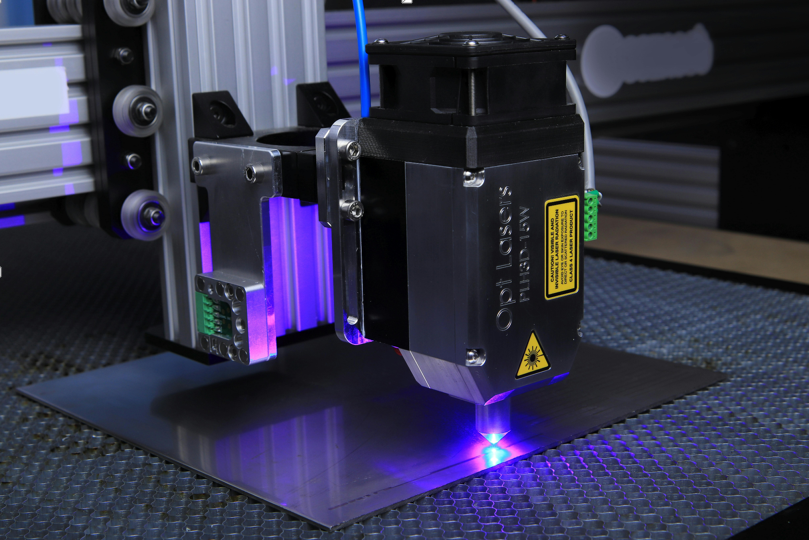

Fibre Laser Cutters

The laser is amplified using optical fibres and helps you cut reflective metals. Fibre laser cutting machines are more efficient than CO2 laser cutters. You can use these laser cutters to cut:

- Organic materials

- Metals

Factors to Consider When Buying a Laser Cutter

A few factors will help you choose the most efficient CNC laser cutting machine for your project.

Power

The machine’s power output determines how much work it has to put into the cutting process. The laser cutters with high power output can cut denser materials. So, you have to choose the machine’s power based on the materials to be cut.

Quality and Price

The best sellers provide quality machines at a reasonable rate. But, the capabilities of all types of laser cutters are not the same.Ensure you have not purchased counterfeit machines, as they will not give the desired output.

Bed Size

The term ‘bed size’ indicates the stage’s X-Y dimensions where you place the material. Your material size will influence the choice of the bed size of your machine. For acrylic cutting, you should use a machine that covers a larger work area. Laser cutters with an adequate bed size provide a space for cutting oversized materials.

See also: Series Kleiner Perkinsann Azevedotechcrunch

Ventilation and Cooling

Current and friction can cause excessive heat generation that affects the machine’s parts. That is why advanced laser cutters are equipped with cooling systems to manage the heat.

Accessories

Many laser cutters have extra functionalities that make your cutting process easier. For instance, you will find accessories to engrave round objects. The presence of optional accessories may affect the machine’s cost.

Conclusion

From material compatibility to cutting speed, different factors influence your decision on buying a laser cutter. An efficient CNC laser cutting machine helps you cut various materials without compromising speed. Check the capabilities and features of the cutter before making a purchase. So, invest in the right machine and streamline your operations.

![[pii_email_5c1227463021bd0531e8]](https://fusionpowertech.com/wp-content/uploads/2023/06/download-16.jpg)