What makes some paint jobs last longer and look better over time? Isn’t it fascinating how an inert layer can protect and preserve paint quality? Inert gases are becoming increasingly popular in the painting industry for this very reason.

Argon gas, in particular, plays a crucial role in enhancing paint durability and ensuring a flawless finish. Here, we will explore how this gas contributes to superior performance. Let’s discover how it can significantly affect the longevity and quality of your projects.

Argon and Its Properties

This gas is known for its non-reactive properties, making it ideal for protecting paint surfaces. Unlike other gases, Argon does not react chemically with the coated surface. This property ensures that the paint remains untainted by external factors, leading to a more consistent finish. Here are additional benefits and uses of this solution that align with its properties:

- Enhanced Stability: It maintains a stable environment, reducing the risk of chemical imbalances that could affect the coating.

- High Purity: The gas is high purity, ensuring no contaminants interfere with application.

- Consistent Performance: It provides uniform protection across various applications, including high-precision tasks.

- Cost Efficiency: Argon’s use can lead to fewer reapplications and corrections, saving costs over time.

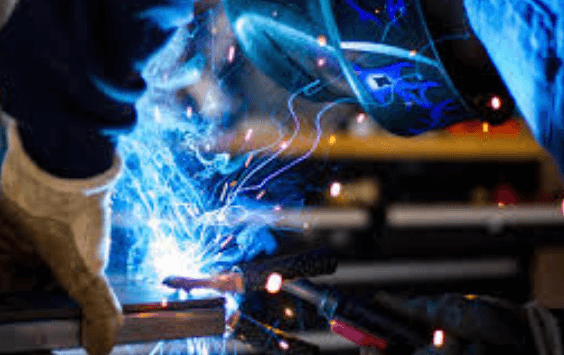

- Versatility in Applications: Useful in various industries beyond painting, such as welding and electronics, where stable environments are crucial.

Preventing Oxidation

Oxidation and rust are common issues that can damage metal surfaces and compromise paint durability. Argon creates an inert atmosphere that effectively displaces oxygen, reducing the chances of oxidation. Thus, it helps maintain the integrity of the metal and the coating, ensuring more durability.

Controlling Moisture

Moisture can adversely affect paint quality by causing issues like bubbling and peeling. This gas helps control moisture levels by providing a dry and stable environment. By regulating humidity, argon ensures that the coating dries evenly and adheres properly. This control prevents moisture-related problems, ensuring the coat adheres well and maintains its quality over time.

Improving Adhesion

Proper adhesion is crucial for a long-lasting finish. This solution contributes to a controlled environment that allows paint to adhere more effectively to the surface. It reduces contaminants and provides a stable atmosphere, helping achieve a more uniform and reliable application. Consequently, the application bonds better, ensuring durability and a high-quality result.

Extending Lifespan

The use of this non-reactive gas significantly improves durability. Protecting the coating from environmental factors like oxygen and moisture ensures that the paint job lasts longer. This extended lifespan means fewer touch-ups and maintenance, providing better value and performance. It also enhances the overall appearance, keeping surfaces looking fresh and well-maintained for longer.

Enhancing Finish Quality

This solution helps create a smoother and more even finish. By preventing defects such as runs and sags, argon ensures that the application looks pristine. Consistent work free from imperfections enhances the visual appeal and adds to the overall durability. A flawless finish not only improves the look but also maximises longevity.

Reducing Drying Time

One benefit of using this solution is faster drying times. By maintaining a controlled environment, argon facilitates quicker evaporation of solvents in the paint. This efficient drying process helps speed up the overall job. Faster drying also reduces the risk of dust and debris settling on the surface before it fully cures.

Minimising Defects

Defects like air bubbles, cracks, and peeling can compromise the quality of such a job. Non-reactive solutions reduce the risk of these issues by providing a stable, inert environment. This also minimises the introduction of contaminants, ensuring a cleaner and more precise application of the coating. This results in a more flawless finish with fewer defects and a more durable coating.

Thus, leveraging the benefits of argon gas can significantly enhance the durability of your paint jobs. The above-mentioned advantages of improved finish are crucial for achieving superior results. Why not take the most of this solution to elevate your painting projects? Consider purchasing from reputable stores to ensure the best quality and performance.