Thread plug gages are critical inspection tools used to verify the acceptability of internal threaded components. A properly calibrated thread plug gage ensures that mating parts assemble correctly, maintain structural integrity, and meet dimensional tolerances outlined in industry standards. Thread plug gage calibration provides the assurance manufacturers need to produce reliable, interchangeable threaded components.

The Role of Thread Plug Gages in Process Control

Thread plug gages serve a go/no-go function by assessing whether an internal thread meets both pitch diameter and thread profile specifications. Since threaded components are common in virtually every manufacturing sector—medical devices, aerospace, automotive, heavy equipment, and electronics—the accuracy of these gages directly affects product quality.

Gage wear occurs naturally from repeated use. Even small dimensional changes can cause improperly accepted parts to move forward in production, creating risks such as assembly failure, leakage, vibration loosening, or fatigue fractures. The solution is routine, traceable thread plug gage calibration performed by an accredited laboratory such as SIMCO.

Standards Governing Thread Gage Calibration

Thread gages are typically calibrated to ASME B1.2, ASME B1.16M, or corresponding ISO metric standards. Calibration involves verifying critical dimensional characteristics including:

- Pitch diameter

- Major and minor diameters

- Lead and flank angles

- Thread form

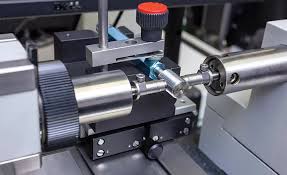

Using precision optical comparators, measurement microscopes, or thread measuring wires, the calibration provider compares actual gage dimensions against nominal specifications.

SIMCO employs disciplined measurement methods to ensure gage accuracy, supporting customers who rely on thread gage performance for regulatory compliance and internal quality systems.

How Thread Plug Gage Calibration Is Performed

The process includes several technical steps:

1. Cleaning and Inspection

Technicians clean the gage using approved solvents, remove embedded debris, and inspect for surface defects or corrosion. Any physical damage can render the gage unsuitable for calibration.

2. Dimensional Verification

Measurements are taken using thread measuring wires or specialized instruments. For go gages, pitch diameter is the primary characteristic. For no-go gages, inspectors verify that the gage is oversized within limits to ensure rejection of nonconforming threads.

3. Form and Lead Assessment

Thread form is evaluated to confirm flank angle symmetry, crest and root shapes, and lead accuracy. Even subtle deviations can affect thread engagement.

4. Certification and Documentation

The calibration provider issues a certificate detailing all measurements, uncertainties, and comparisons to nominal values. This documentation is essential for quality audits and process validation.

Benefits of Routine Calibration

Regular thread plug gage calibration:

- Prevents acceptance of defective threaded parts

- Reduces scrap and rework costs

- Ensures assembly reliability

- Maintains compliance with manufacturing standards

- Extends gage life by identifying early wear

SIMCO’s calibration services offer consistent dimensional accuracy for gage sets of all sizes, ensuring reliable inspections throughout production cycles. You can review their service approach at https://www.simco.com/about-us/.

![[pii_email_1005f45dfe415af52d61]](https://fusionpowertech.com/wp-content/uploads/2023/05/images-8-1.jpg)