Traditional ceramics are known for their exceptional hardness and heat resistance, but they have a well-known weakness: brittleness. When subjected to impact or stress, they tend to fracture rather than bend. To overcome this limitation, material scientists developed composite ceramics. These advanced materials combine a ceramic matrix with a reinforcing phase, creating a new class of materials with enhanced toughness, strength, and reliability.

By engineering materials at a microscopic level, composite ceramics merge the best attributes of different components to achieve performance that neither could deliver alone. This article explores the world of these remarkable materials, covering their unique properties, different types, and the diverse applications where they are pushing the boundaries of technology.

What Exactly Are Composite Ceramics?

Composite ceramics are multi-phase materials where a ceramic matrix is reinforced with a secondary phase. This reinforcement can be in the form of particles, whiskers, or fibers. The primary goal is to improve the fracture toughness of the base ceramic, making it more resistant to cracking and catastrophic failure.

The concept is simple: if a crack starts to form in the brittle ceramic matrix, its path is interrupted by the reinforcing material. The reinforcement can deflect the crack, bridge it, or absorb its energy, effectively stopping it from spreading. This mechanism significantly enhances the material’s durability and damage tolerance.

The two main components of composite ceramics are:

- The Matrix: This is the primary ceramic material that holds the reinforcement together. Common matrix materials include silicon carbide (SiC), silicon nitride (Si₃N₄), alumina (Al₂O₃), and zirconia (ZrO₂). The matrix provides the characteristic high-temperature stability and hardness of a ceramic.

- The Reinforcement: This is the secondary phase added to the matrix to improve its mechanical properties. It can be made from various materials, including carbon, silicon carbide, or other ceramics. The shape and distribution of the reinforcement play a crucial role in the final properties of the composite.

Key Properties and Benefits of Composite Ceramics

The unique combination of matrix and reinforcement gives composite ceramics a set of properties that make them superior to monolithic (single-phase) ceramics in many demanding applications.

Enhanced Fracture Toughness

The most significant benefit of composite ceramics is their improved fracture toughness. While traditional ceramics might shatter under a sudden load, composite versions can withstand greater stress and impact. This “graceful failure” behavior is critical in applications where reliability and safety are paramount, such as in aerospace components or medical implants.

High Strength-to-Weight Ratio

Many composite ceramics are remarkably strong yet lightweight. This high strength-to-weight ratio makes them an attractive alternative to metal alloys in applications where reducing weight is a priority. For example, using them in aircraft engines or vehicle brake systems can lead to significant fuel savings and improved performance.

Superior Thermal Shock Resistance

Thermal shock occurs when a material experiences a rapid temperature change, causing stress that can lead to cracking. The reinforcing phase in composite ceramics helps to mitigate these stresses, giving them excellent resistance to thermal shock. This makes them ideal for environments with extreme temperature fluctuations, like rocket nozzles and high-performance braking systems.

Excellent Wear and Corrosion Resistance

Like their monolithic counterparts, composite ceramics are extremely hard and chemically inert. This gives them outstanding resistance to wear, abrasion, and corrosion. They can operate in harsh chemical environments and high-friction conditions where metals would quickly degrade. This durability extends the service life of components and reduces maintenance costs.

Major Types of Composite Ceramics

Composite ceramics can be classified based on the type and form of reinforcement used. The three main categories are particle-reinforced, whisker-reinforced, and fiber-reinforced composites.

1. Particle-Reinforced Composites

In these composites, small, equiaxed ceramic particles are dispersed throughout the matrix. The particles are typically made of a hard material like silicon carbide or titanium carbide. Their primary role is to obstruct the movement of cracks. As a crack propagates through the matrix, it encounters these hard particles, forcing it to change direction and expend more energy. This toughening mechanism is effective and relatively inexpensive to implement, making particle-reinforced composites common in cutting tools and wear-resistant components.

2. Whisker-Reinforced Composites

Whiskers are tiny, single-crystal fibers that are extremely strong. When embedded in a ceramic matrix, these whiskers act as powerful crack deflectors. They can also “pull out” of the matrix as a crack tries to open, a process that absorbs a significant amount of energy and boosts toughness. Alumina reinforced with silicon carbide whiskers is a classic example, known for its exceptional strength and hardness. These materials are often used in advanced cutting tools for machining hard metal alloys.

3. Fiber-Reinforced Composites (Ceramic Matrix Composites – CMCs)

Fiber-reinforced composites represent the most advanced and toughest class of composite ceramics. In these materials, continuous or chopped fibers are embedded within the ceramic matrix. The fibers, often made of carbon (C) or silicon carbide (SiC), carry most of the load, while the matrix protects the fibers from the environment and transfers the load between them.

These materials, often called Ceramic Matrix Composites (CMCs), are so tough they behave almost like a metal, exhibiting a degree of “give” before failing. This high-end performance makes them essential for the most demanding applications, including:

- Turbine blades and shrouds in jet engines.

- Brake discs for high-performance cars and aircraft.

- Thermal protection systems for spacecraft re-entry vehicles.

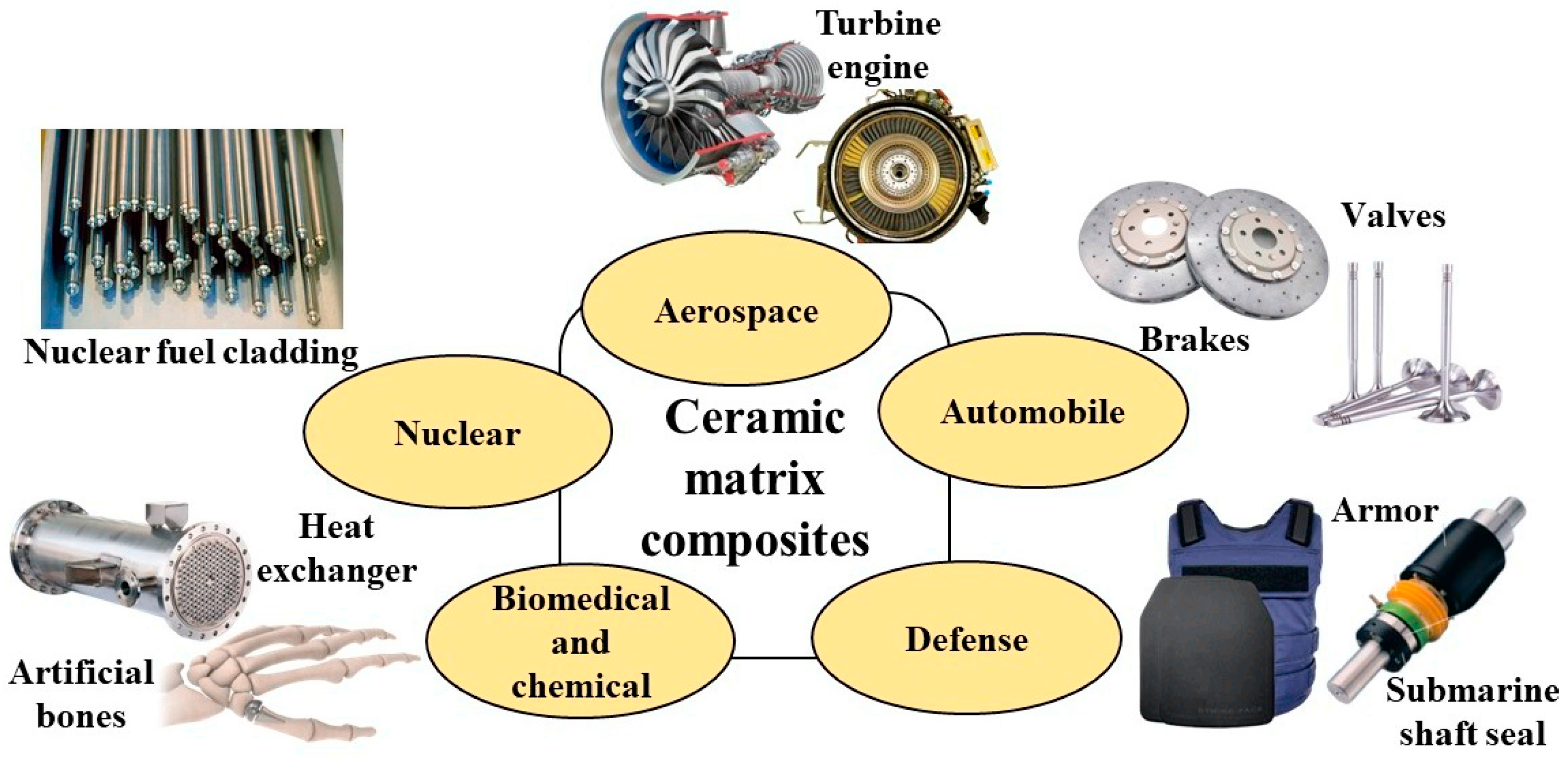

Common Applications Across Industries

The exceptional properties of composite ceramics have opened doors to innovation in numerous high-tech fields.

- Aerospace: CMCs are revolutionizing jet engine design. By replacing heavy nickel superalloys with lightweight CMCs in hot sections, engines can run hotter and more efficiently, reducing fuel consumption and emissions. They are also used for thermal protection panels on hypersonic vehicles.

- Automotive: High-performance sports cars and luxury vehicles use carbon-ceramic brake discs. These composite ceramics are lightweight, fade-resistant, and can withstand the extreme temperatures generated during aggressive braking without warping.

- Industrial and Manufacturing: The hardness and wear resistance of particle- and whisker-reinforced composites make them ideal for cutting tools, grinding wheels, and wear parts in industrial machinery. Their long service life reduces downtime and improves productivity.

- Biomedical: The biocompatibility and strength of certain composite ceramics make them suitable for medical implants, such as hip joints and dental restorations. Their wear resistance is a key advantage for long-lasting orthopedic implants.

- Energy: Components in gas turbines for power generation, heat exchangers, and parts for nuclear reactors can benefit from the high-temperature stability and corrosion resistance of composite ceramics.

Frequently Asked Questions (FAQs)

What is the main difference between a ceramic and a composite ceramic?

A traditional (monolithic) ceramic consists of a single phase, while a composite ceramic is a multi-phase material. It contains a primary ceramic matrix that is reinforced with a secondary phase (particles, whiskers, or fibers) to improve its properties, particularly its fracture toughness.

Read Also: Threads Api Techmeme Hootsuitemehtatechcrunch

Are composite ceramics expensive to produce?

The cost of composite ceramics varies greatly depending on the type. Particle-reinforced composites are relatively affordable. However, high-performance fiber-reinforced composites, or CMCs, can be very expensive to manufacture due to the high cost of the fibers (like carbon or SiC) and the complex, multi-step processing required to create the final component.

Why are CMCs used in jet engines?

Ceramic Matrix Composites (CMCs) are used in the hot sections of jet engines because they are lighter than the metal superalloys they replace and can withstand higher temperatures. This allows the engine to operate more efficiently, burning less fuel and producing fewer emissions. Their light weight also contributes to overall performance gains.

Can composite ceramics break?

Yes, all materials will eventually fail under sufficient load. However, the key advantage of composite ceramics is their failure mode. Unlike monolithic ceramics that can shatter catastrophically, composites are designed to fail “gracefully.” The reinforcement mechanisms provide resistance to crack growth, meaning they can often sustain some damage without immediate, complete failure.

Are composite ceramics used in consumer products?

Yes, though they are most common in high-end applications. The most well-known consumer application is carbon-ceramic brake discs found on high-performance sports cars. Some premium knives also use particle-reinforced ceramic blades for enhanced sharpness and durability.

Final Words

Composite ceramics represent a significant leap forward in materials science. By cleverly combining different materials, engineers have overcome the inherent brittleness of traditional ceramics while retaining their most valued traits like heat resistance and hardness. The result is a class of materials that are tougher, stronger, and more reliable under extreme conditions.

From making air travel more efficient to improving the performance of high-end vehicles and extending the life of industrial tools, the impact of these advanced materials is already significant. As research continues to refine manufacturing processes and develop new matrix-reinforcement combinations, composite ceramics are poised to play an even greater role in shaping the future of technology, enabling innovations that were once considered impossible.